Gasdruckfedern

Gasdruckfedern werden weltweit immer häufiger eingesetzt. Sie ermöglichen eine nahezu konstante Kraft über den gesamten Federweg. Dies bietet in vielen Anwendungen entscheidende Vorteile. Daher liefern wir Ihnen eine große Auswahl an Gasdruckfedern, die im Standardkatalog AMDL oder auf Anfrage erhältlich sind.

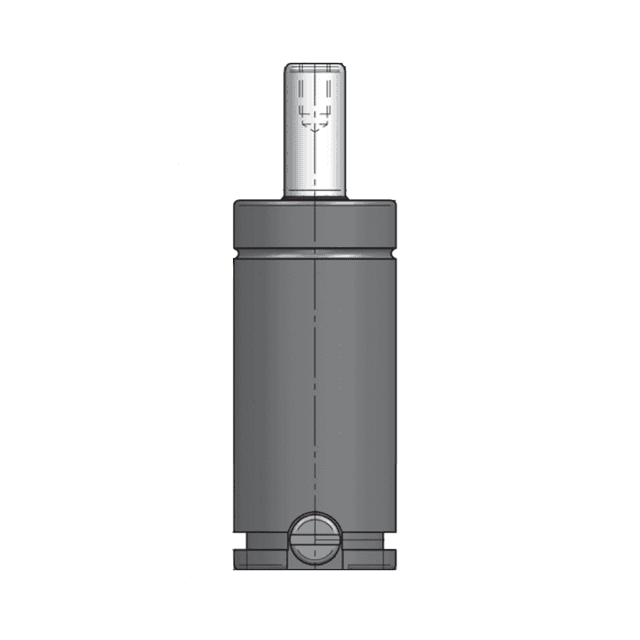

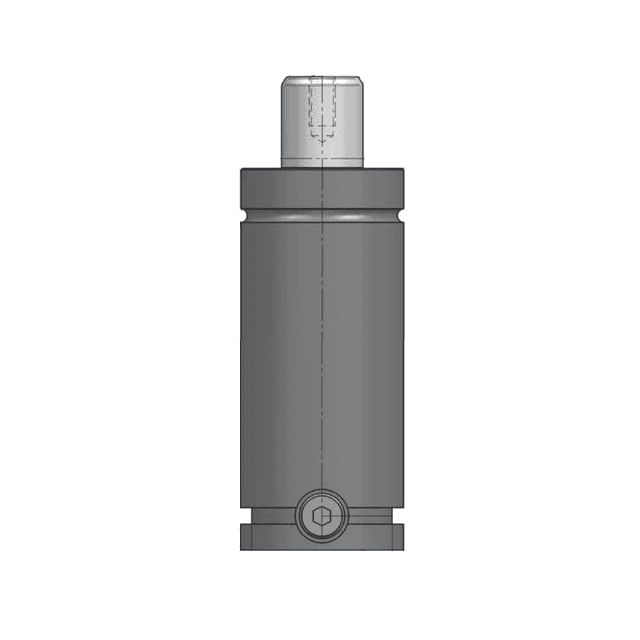

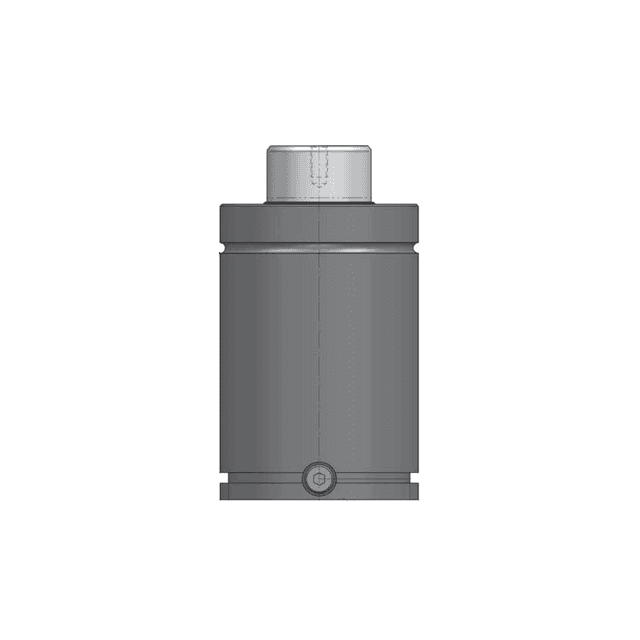

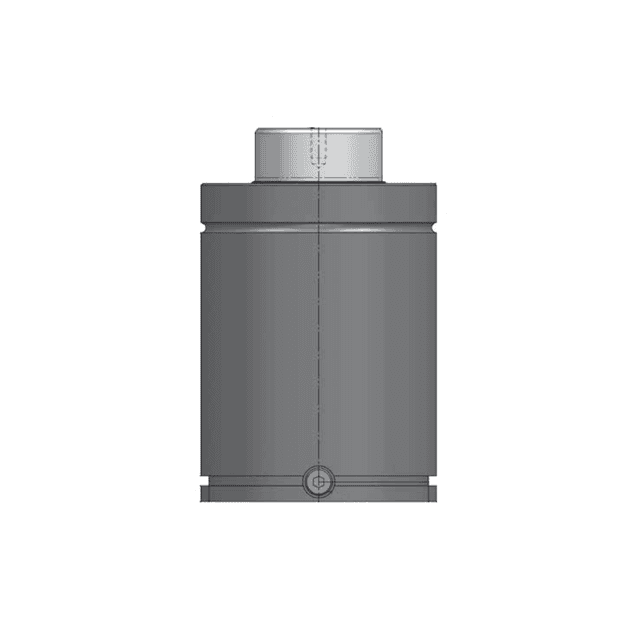

Mini gas springs AFB

Mini gas springs AFJ

Mini gas springs AFC

Mini gas springs AF V1

Standard ISO gas springs AG 150

Standard ISO gas springs AG 250

Standard ISO gas springs AG 500

Standard ISO gas springs AG 750

Standard ISO gas springs AG 1500

Standard ISO gas springs AG 3000

Standard ISO gas springs AG 5000

Standard ISO gas springs AG 7500

Standard ISO gas springs AG 10000

Heavy duty gas springs CM 350 V1

Heavy duty gas springs CM 500 V2

Heavy duty gas springs CM 1000 V1

Heavy duty gas springs CM 1500 V2

Heavy duty gas springs CM 2500 V1

Heavy duty gas springs CM 4000 V1

Heavy duty gas springs CM 6500 V1

Heavy duty gas springs CM 10000

Die Gasdruckfedern der Firma AMDL

Als Partner von AzolGas bieten wir eine große Auswahl von unterschiedlichen Gasdruckfedern für alle Anwendungen an. Die Gasdruckfedern sind in verschiedenen Größen erhältlich (ISO-Standard-Gasdruckfedern, Mini-Gasdruckfedern, Kompakt-Gasdruckfedern usw.) und bieten eine sehr hohe Lebensdauer, Korrosionsbeständigkeit und sind außerdem einfach zu befestigen. Sie eignen sich hervorragend für Tiefziehanwendungen.

AzolGas ist seit 1982 auf das Design, die Entwicklung und die Herstellung von Gasdruckfedern spezialisiert. Mit einer eigenen Abteilung für Forschung und Entwicklung garantieren AzolGas-Druckfedern ein qualitativ hochwertiges Produkt, das immer an der Spitze der Innovation steht. Azolgas-Druckfedern sind nach ISO 9001 und ISO 14001 zertifiziert.

Die Vorteile von Gasdruckfedern

Gasdruckfedern haben viele Vorteile, die sie zu interessanten Alternativen machen. Der erste ist, dass sie im Vergleich zu Draht- oder Elastomerfedern eine höhere Kraft bei geringerem Platzbedarf liefern können. Außerdem ist diese Kraft über die gesamte Hublänge nahezu linear. Dadurch können mehrere Drahtfedern ersetzt und die Anzahl der Federn und Senkungen reduziert werden.

Wie wählt man eine Gasdruckfeder aus?

Um eine Gasdruckfeder zu bestimmen, müssen Sie mehrere Parameter berücksichtigen. Erster Schritt ist die Ermittlung der notwendigen Hublänge und der erforderlichen Kraft. Anhand dieser Elemente lassen sich die folgenden 6 Parameter bestimmen:

- Durchmesser der Gasdruckfeder

- Länge L1

- Kraft

- Durchmesser des Schafts

- Art der Befestigung : Wenn mit Flansch die Montage

Für weitere Informationen wenden Sie sich bitte an unser Verkaufsteam.

Die Montage von Gasdruckfedern

Die strikte Einhaltung der Anweisungen für die Montage von Gasdruckfedern ist entscheidend, um die Sicherheit und die Lebensdauer des Werkzeugs und der Federn zu gewährleisten.

Die Gasdruckfeder muss den technischen Vorgaben entsprechend befestigt und eingesetzt werden. Die Belastung darf nicht seitlich auf die Kolbenstange erfolgen. Aus Sicherheitsgründen wird empfohlen nur 90 % des möglichen Hubes der Gasdruckfeder zu nutzen.

Achtung: Wenn der Federkörper in Öl gebadet wird, besteht die Gefahr, dass die Dichtungen durch das Öl und die Feilspäne beschädigt werden. Wenn das Öl in den Zylinderkörper gelangt, hat er einen Druckanstieg zur Folge.