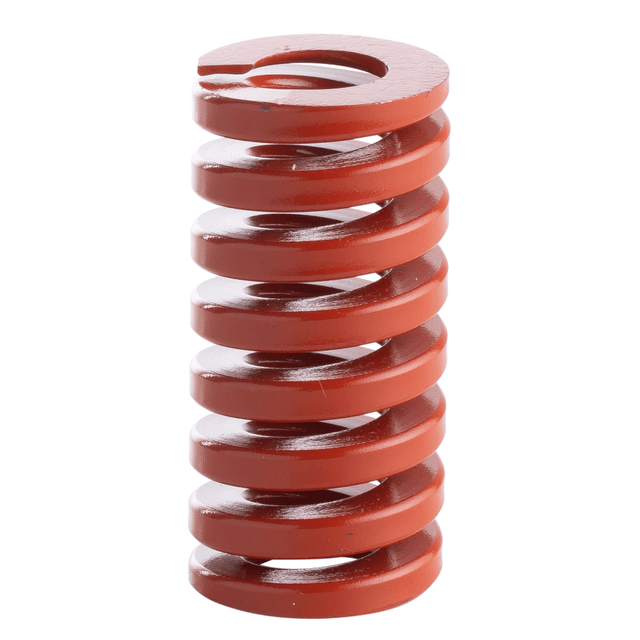

Compression springs

Compression wire springs are widely used in various industries, including press tooling. Installed on side clamps or strip lifters, they ensure proper sheet metal retention during the downstroke phase by exerting force on the side clamp, ensuring the efficiency and quality of the operation. Explore our range of wire springs with our four distinct load classes.

Light load compression springs S11 - ISO 10243 rectangular wire

Light load compression springs R11 - ISO 10243 round wire

Medium load compression springs S21 - ISO 10243 rectangular wire

Medium load compression springs R21 - ISO 10243 round wire

Heavy load compression springs S26 - ISO 10243 rectangular wire

Heavy load compression springs R26 - ISO 10243 round wire

Extra-heavy load compression springs S36 - ISO 10243 rectangular wire

MDL Brand Wire Springs

MDL brand compression springs offer a solution for all your needs with a wide variety available in our catalogue. Our helical compression springs are globally recognized for their quality and strength, manufactured according to DIN ISO 10243 standard. The force exerted by the springs ensures the proper retention of the sheet metal during the punches' downstroke phase. This force must be significant enough to ensure sheet metal retention during the stamping phase while allowing slight slippage for proper material flow.

Load Classes:

Our springs are available in four different load classes, each distinguished by a color-coded level of resistance:

- Green compression springs for light loads

- Blue compression springs for medium loads

- Red compression springs for heavy loads

- Yellow compression springs for extra-heavy loads

Recommended Strokes According to Load Class:

Load classes | Green | Blue | Red | Yellow |

|---|---|---|---|---|

S1 Recommended total stroke for long-term use | 25% of Lo | 25% of Lo | 20% of Lo | 17% of Lo |

S2 Recommended total stroke for medium-term use | 30% of Lo | 30% of Lo | 25% of Lo | 20% of Lo |

S3 Maximum total working stroke | 40% of Lo | 37.5% of Lo | 30% of Lo | 25% of Lo |

Lo : initial length

Spring Design:

Our compression springs are manufactured through drawing, resulting in an extended lifespan compared to springs produced by rolling, a process that induces more stresses during production. They are made from chrome vanadium silicon steels to ensure their strength. The manufacturing process, once the wire is produced, follows these steps:

- Wire coiling

- Degassing

- End grinding

- Degreasing

- Painting

This strict process ensures the quality of our springs. A stringent quality control is performed after each stage to guarantee the lifespan of our springs.

Spring Lifespan

The lifespan of a spring depends on several factors related to its use, making it challenging to guarantee. However, under normal usage conditions, we can state that the springs can withstand:

- 50,000 press strokes at maximum working stroke

- 500,000 press strokes at medium working stroke

- 2 million press strokes at recommended working stroke

Standard Shapes

Our springs are available in the catalogue in two wire shapes: rectangular wire springs denoted by the letter S, and round wire springs denoted by the letter R. Each of these wire shapes is available in stock and will be sent to you within 48 hours.

Wire Spring Preload

Preload is a crucial element for helical compression springs.

Preload serves two purposes:

- Ensuring the spring's lifespan by preventing resonance/vibration

- Providing immediate force when the side clamp is in contact with the sheet

The preload is approximately 20% of the working stroke.

Standard Dimensions of Our Wire Springs

Standard outer diameters: 10mm, 12.5mm, 16mm, 20mm, 25mm, 32mm, 40mm, 50mm, 63mm

Standard lengths: 25mm, 32mm, 38mm, 44mm, 51mm, 64mm, 76mm, 89mm, 102mm, 115mm, 127mm, 140mm, 152mm, 178mm, 203mm, 254mm, 305mm

We also create custom springs as needed.

How to Choose Your Wire Spring ?

To choose the wire spring, consider several parameters. The first step is based on the tool's stroke and the required force. These elements help determine the following four parameters:

- Hole diameter

- Inner diameter (or rod diameter)

- Free length

- Load (rate) in daN/mm

With this information, you can select your spring in our catalogue! If you need assistance, don't hesitate to contact us; our team is here to help.