Punches

Cutting punches are the active elements of your tool, enabling proper cutting, folding, or forming of your pieces. Our range of standard cutting elements is available in our catalogue with over 9,000 punches references kept in stock and machined to your specifications. We also create custom punches according to your drawings to meet all your needs.

Headed punches ISO P_-PPNB / P_-PPN_ - ISO 8020

Headed punches ISO with ejector PB-PPEB / PB-PPE_ - ISO 8020

Heavy duty headed punches P_-PTNB / P_-PTN_

Heavy duty headed punches with ejector P_-PTEB / PB-PTE_

Micro headed punches P_-PSNB / P_-PSN_

Headed pilots punches PB-PPNP / P_-PPNZ - ISO 8020

Tapered head punches PB-RFNB / PB-RFN_

Tapered head punches with ejector PB-RFEB / PB-RFE_

Conical head punches 60° P_-TFNB / P_-TFN_

Conical head punches 60° with ejector P_-TFEB / P_-TFE_

Conical head punches 30° PB-TTNB / PB-TTN_

Conical head punches 30° with ejector PB-TTEB / PB-TTE_

Ball-lock punches for light duty P_-BLNB / P_-BLN_

Ball-lock punches for heavy duty P_-BHNB / P_-BHN_

Ball-lock punches for light duty with ejector PB-BLEB / PB-BLE_

Ball-lock punches for heavy duty with ejector PB-BHEB / PB-BHE_

Ball-lock punches for light duty with point larger than shank P_-BJNB / P_-BJN_

Ball-lock punches for heavy duty with point larger than shank P_-BKNB / P_-BKN_

Headed punches with center dowel P_-PPDB / P_-PPD_

Headed punches with center dowel and ejector P_-PPFB / P_-PPF_

Heavy duty headed punches with center dowel P_-PTDB / P_-PTD_

Heavy duty headed punches with center dowel and ejector P_-PTFB / P_-PTF_

Headed punches DIN PB-PANB / PB-PAN_

Standard Punches

Our range of standard punches from the Porter Besson brand is available in stock with different types of heads to adapt to various needs:

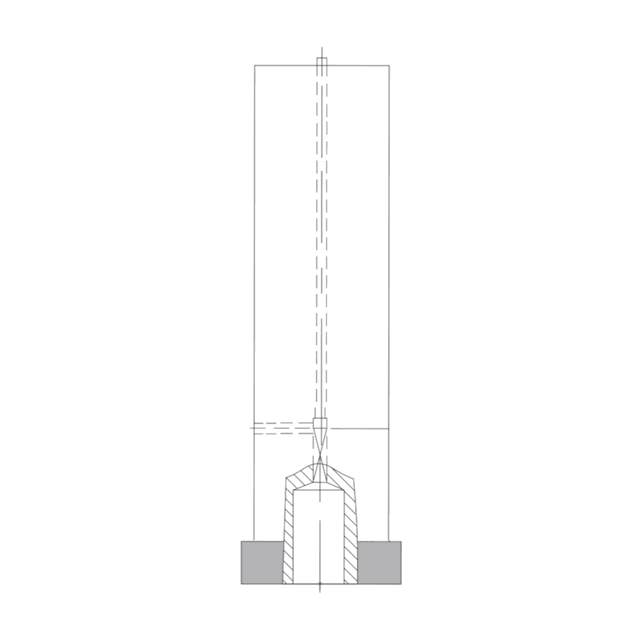

Cylindrical Head Punches:

Cylindrical head punches with a 5mm head and 8mm head for heavy work are available in stock with or without an ejector*. Cylindrical head punches are advantageous for easy implementation and precise orientation due to a highly accurate alignment plate. We also have a range of pilot punches with cylindrical heads for guiding the strip.

Micro Cylindrical Head Punches:

Micro series cylindrical head punches have a 3mm head. The low head thickness reduces punch bulkiness and allows punches to be positioned closer together. They can also be used as ejectors.

Conical Head Punches:

Conical head punches are available in stock with either a 60° or 30° angle, with or without an ejector*. They have reduced space requirements, allowing for closer punch spacing compared to other head types. This is ideal for perforated sheet applications where closely spaced punches are needed. We also offer conical heads with a 60° angle in various diameters.

Ball Lock Punches:

Ball-lock punches are available for both light-duty and heavy-duty applications, with or without an ejector*. They allow for easy and quick punch removal without touching the punch holder, thanks to a ball-lock mechanism, reducing downtime.

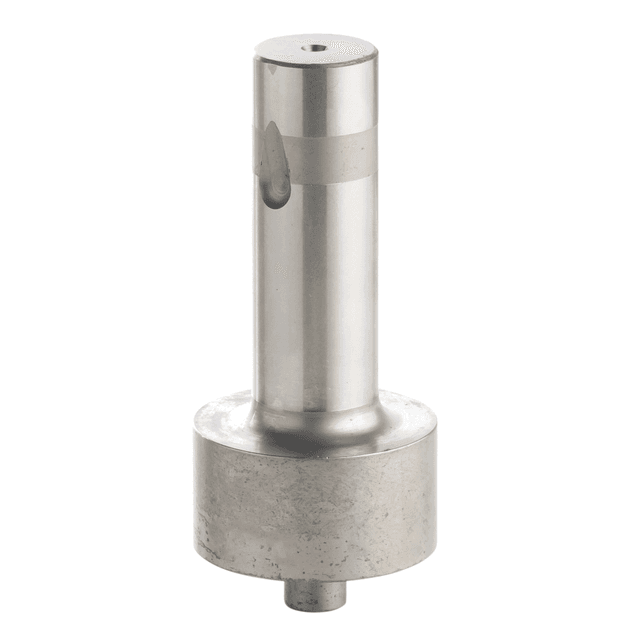

Bottleneck Punches:

Bottleneck punches are available in stock with or without an ejector*. They ensure a better distribution of the shockwave, guaranteeing head strength even in extreme usage conditions.

*The ejector facilitates waste removal.

All our punches can be coated to suit your needs.

Materials

Our punches are available in several materials, each with different properties:

Material A Z160CDV12 : 12% Chromium Highly Alloyed Steel

High Hardness : 58 - 62 HRc

Used for thin sheets and low to medium hardness.

Note: An additional tempering process is required for coating.

Material B Acier rapide HSS : Z90WDCV

High Hardness : 60 - 64 HRc

Used for hard sheets (Stainless Steel / High strength steel...)

Material C Carbide

The hardest material we can offer. Very brittle. This material is used for high-speed applications and flat cuts only (not compatible with lateral forces).

Material E ASP 23

High Hardness: 62 - 66 HRc

Sintered High-Speed Steel (powder technology). Less fragile, resistant to breakage. Very good compression resistance.

Material K X110 CrMoV8 - T6

High Hardness: 61 - 63 HRc

Combines the hardness of Material B with the resilience of Material A. This material offers an excellent technical compromise.

Material S M4/1.3351/HS 6.5.4

High Hardness: 62 - 66 HRc

If you have a specific material requirement, please let us know, and we will assess its feasibility.

Dimensions

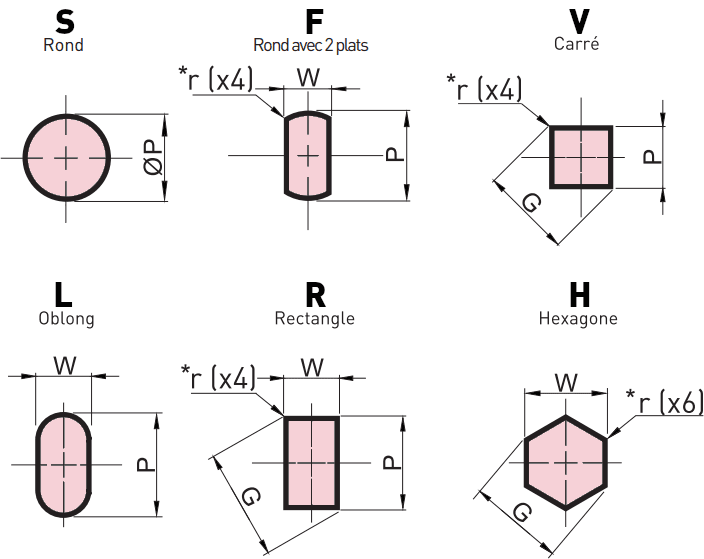

Punches are characterized by the following dimensions:

Body Diameter (D)

Total Length (L)

Working Length (L2)

Form Dimension: P and W for form dimensions.

Form Orientation (form punches are oriented using an alignment plate).

All these dimensions should be specified in your price inquiries.

Custom Punches

As a manufacturer and expert, we can also make all your special cutting punches to drawings that complement our range of standard catalogue cutting punches, which are managed from stock and can therefore be delivered immediately. Simply email us your drawing and our sales and technical team will deal with your request within 48 hours. We've been specialists in special cutting punches for nearly 65 years, so we'll be able to meet your needs efficiently and technically.